The pharmaceutical along with cosmetic and food industries underwent major developments regarding the delivery methods of active ingredients to specified areas during the past years. The development of Nano Emulsion Technology Pump System techniques enables scientists to make microscopic emulsion systems that enhance the availability and stability and potency of different compounds.

The pairing of state-of-the-art pump systems coming together with this technology creates fundamental changes to how products are formulated while also changing how they get dispensed. This piece examines the powerful bond between nano emulsions and pump systems as they transform numerous industrial sectors.

What is Nano Emulsion Technology?

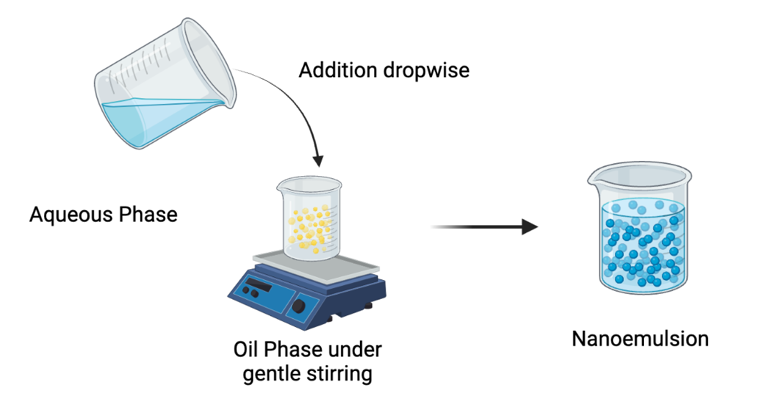

Nanometer-scale droplet emulsions emerge through nano emulsion technology by reducing immiscible water and oil mergers down to dimensions between 20–200 nm. Faster drug absorption coupled with improved stability results from the tight droplet size in nano emulsions which increases their overall surface area.Nano emulsion technology proves highly valuable for pharmaceutical applications by improving poorly soluble drug bioavailability while cosmetics gain advantage from active ingredient penetration to improve skin penetration.Benefits of Nano Emulsion Technology

Benefits of Nano Emulsion Technology

The nanoscale reduction of droplets boosts hydrophobic compounds’ solubility in water thus improving their body absorption.The stability of nano emulsions exceeds that of conventional emulsions. The tiny size of the formulation together with surfactants achieves stability through preventing separation between the phases along with maintaining steady uniformity.

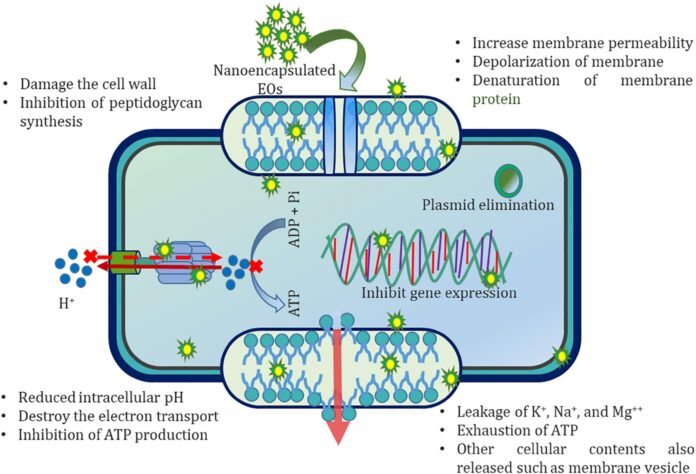

Nano emulsion systems offer controlled substance release properties which make them well-suited for delivering medication consistently over time in pharmaceutical and cosmetic products.Nano emulsions become useful for drug delivery systems through their ability to achieve targeted tissue or cell delivery.

The Role of Nano Emulsion Technology Pump System

The effectiveness of nano emulsions leads to storage and dispensation problems as well as delivery complications. Droplet dimensions and characteristics need pumps which deliver precise amounts while serving users easily in a reliable manner. The application of nano emulsion technology requires pump systems because they serve fundamental purposes.Medical solutions containing active nanoparticles need exact measurements for obtaining therapeutic benefits from nano emulsions.

The controlled nature of pump systems makes sure the right amounts of the nanoemulsion get dispensed properly. The accurate dosage requirements in pharmaceutical and personal care products necessitate pump systems specifically because of their vital role.Nano emulsion systems remain at their best when protected from various types of contaminants because they show increased sensitivity to environmental contact.

The closed loop nature of pumps protects nano emulsion integrity through system containment that blocks air contact. The delivery of nano emulsions needs proper pressure regulation which ensures droplet structure remains intact. The sophisticated pump technology particularly peristaltic pumps or diaphragm pumps protects nano-sized droplets from breakage when transferring emulsion solutions. A pump system delivers nano emulsions with consistent amounts at every operating cycle because of its reliable operation profile.

The pharmaceutical and food production industries need uniform active ingredient distribution because quality control demands it. Large-scale production benefits from integrated pump systems because they form part of automated filling and packaging lines to achieve efficient manufacturing. The automated system eliminates human mistakes and enhances the production capacity of nano emulsion products.

Applications of Nano Emulsion Technology Pump System

The pharmaceutical field experienced revolutionary changes because ofگونه Nano emulsion technology in creating drug delivery systems. Nano emulsions used in oral drug formulations provide better solubility for drugs while enhancing their absorption levels.

The implementation of precise pump systems provides patients with precise dosage distribution through accurate delivery while also simplifying their treatment process.

The cosmetics sector utilizes nano emulsion technology to introduce vitamins antioxidants and peptides along with active ingredients deep into the skin layers.

A properly designed pump system distributes the elements precisely and uniformly resulting in improved product performance.The food and beverages sector utilizes nano emulsions for improving delivery methods of nutrients together with vitamins and flavors.

Industrial pumps with accurate control mechanisms enable precise dosage control which leads to consistent delivery of emulsions in every batch production.

The application of nano emulsions in agriculture involves their use for delivering pesticides along with herbicides and fertilizers through precise dispensing systems. The combination of pump systems allows products to be distributed efficiently and practically waste-free which results in better crop outcomes with minimized environmental impact.

Challenges and Future Outlook for Nano Emulsion Technology Pump System

The combination of nano emulsion technology and pump systems brings significant advantages but requires solutions to several emerging difficulties. The stability of nano emulsiThe performance of nano emulsion solutions is at risk when subjected to external stressors that include temperature changes and exposure to light while encountering shear forces during fluid movement with pumps. Manufacturers continuously innovate to enhance the stability properties of these emulsions in order to extend their product lifetime.

The production scalability of nano emulsion faces difficulties because the formulation process is complex and specialized equipment such as pumps are necessary to handle droplets at the nano-scale.Conclusion:Nano emulsion innovation, when joined with cutting edge siphon frameworks, is preparing for more productive, exact, and stable conveyance of dynamic fixings across different enterprises.

Whether it’s further developing medication bioavailability, upgrading skincare items, or expanding the adequacy of food added substances, the cooperative energy between Nano Emulsion Technology Pump System and siphon frameworks is changing the way that we convey fundamental mixtures. As the two advances keep on developing, we make certain to see considerably additional pivotal advancements in the years to come.